Incomplete quenching heat treatment processing

Release time:2023.03.12

Browse:464

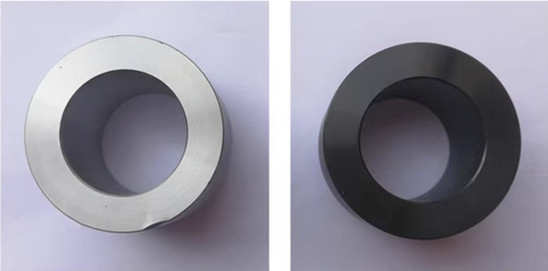

Incomplete quenching refers to the heat treatment process of heating hypereutectoid (and eutectoid) steel to a temperature between Ac1 and Acm, followed by rapid cooling after insulation (see Figure 2-2). Mainly suitable for non alloy tool steel and low alloy tool steel.

Advantages of incomplete quenching of hypereutectoid steel:

① Quenching heating

The low temperature retains a certain amount of undissolved granular carbides, which gives the steel high hardness and wear resistance after quenching;

② Low heating temperature, fine austenite grains, and better mechanical properties can be obtained after quenching;

③ The tendency for oxidation, decarburization, distortion, and cracking is small.

Advantages of incomplete quenching of hypereutectoid steel:

① Quenching heating

The low temperature retains a certain amount of undissolved granular carbides, which gives the steel high hardness and wear resistance after quenching;

② Low heating temperature, fine austenite grains, and better mechanical properties can be obtained after quenching;

③ The tendency for oxidation, decarburization, distortion, and cracking is small.

Previous article:Classification of stainless steel

✕